The process of making a traditional Vietnamese palm hat, also known as a "nón lá," involves several steps and requires skilled craftsmanship. Here's an overview of the typical process:

-

Harvesting Palm Leaves: The process starts with harvesting palm leaves. The leaves are typically sourced from palm trees that are abundant in Vietnam, such as the "nypa fruticans" or "borassus flabellifer."

-

Soaking and Softening: Once harvested, the palm leaves are soaked in water to make them pliable and easier to work with. This softens the leaves and prepares them for the shaping process.

-

Cutting and Shaping: After soaking, the leaves are cut into strips of appropriate width for weaving. These strips are then shaped into the conical form characteristic of the nón lá. This step requires skill and precision to achieve the desired shape and size.

-

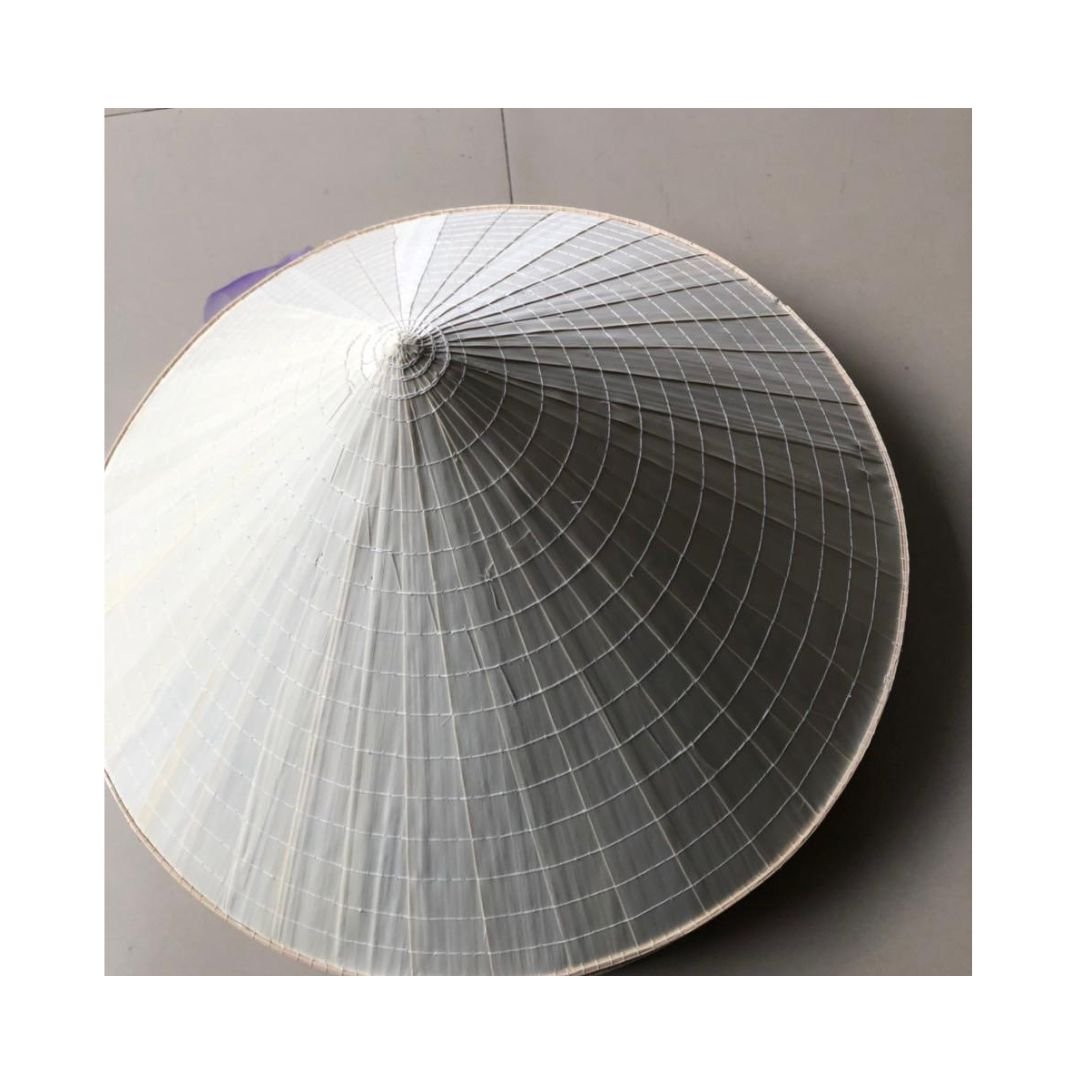

Weaving: The weaving process begins by interlacing the palm strips to form the conical structure of the hat. Skilled artisans use traditional weaving techniques passed down through generations to create intricate patterns and designs on the hat.

-

Forming the Brim: As the weaving progresses, the brim of the hat is formed by gradually widening the woven structure. This creates a broad, circular brim that provides shade and protection from the sun.

-

Trimming and Finishing: Once the weaving is complete, the excess palm strips are trimmed, and the edges of the hat are finished neatly. Any loose ends or rough edges are carefully smoothed out to create a clean, polished look.

-

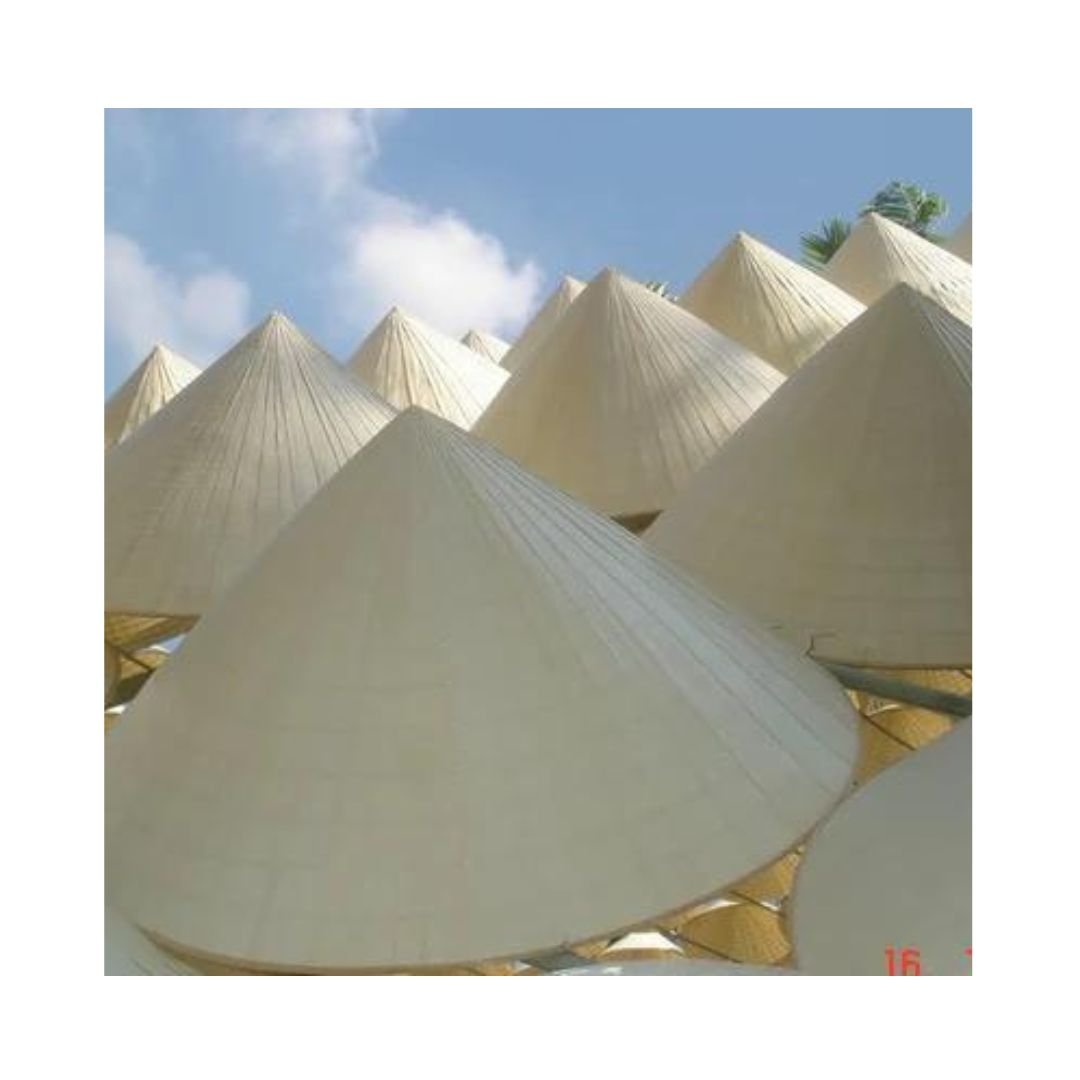

Drying and Shaping: The finished hat is allowed to dry naturally in the sun, which helps to set its shape and strengthen the palm fibers. During this stage, the hat may be placed on a mold or form to ensure it retains its conical shape as it dries.

-

Decorating (Optional): Depending on the desired style and design, the palm hat may be decorated with additional elements such as colorful ribbons, embroidery, or painted motifs. These decorative touches add personality and flair to the finished hat.

-

Final Inspection: Once fully dried and decorated, the palm hat undergoes a final inspection to ensure quality and craftsmanship. Any imperfections are addressed, and adjustments may be made as needed to ensure the hat meets the desired standards.

-

Packaging and Distribution: The completed palm hats are packaged and prepared for distribution to local markets, souvenir shops, or export markets where they are sold and appreciated for their craftsmanship and cultural significance.